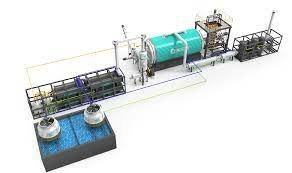

Thermal desorption units (TDUs) are innovative technologies used for the remediation of contaminated soil, sediments, and sludges by removing or separating volatile and semi-volatile organic compounds (VOCs and SVOCs) through controlled heating. TDUs play a crucial role in environmental remediation efforts, providing a cost-effective and efficient solution for treating contaminated materials. This article aims to delve into the workings of thermal desorption units, their applications, and their benefits in environmental remediation.

Working Principle of Thermal Desorption Units: Thermal desorption unit operates on the principle of thermal desorption, a process that involves heating contaminated materials to temperatures sufficient to volatilize and separate organic contaminants from the matrix. The process typically consists of the following steps:

-

Feedstock Preparation: Contaminated soil, sediment, or sludge is fed into the thermal desorption unit after undergoing pretreatment to remove large debris and enhance processing efficiency.

-

-

Heating: The feedstock is heated within the desorption chamber of the unit to temperatures ranging from 200°C to 600°C, depending on the specific contaminants and matrix characteristics. Heating is conducted in an oxygen-limited or inert atmosphere to prevent combustion.

-

-

Volatilization: As the temperature increases, organic contaminants within the feedstock volatilize and vaporize, becoming gaseous compounds. These volatile and semi-volatile organic compounds are then separated from the solid matrix.

-

-

Off-Gas Treatment: The vaporized contaminants, along with any moisture present in the feedstock, are extracted from the desorption chamber as off-gas streams. Off-gas treatment systems, such as thermal oxidizers or activated carbon adsorption units, are employed to treat and remove contaminants before discharge to the atmosphere.

-

-

Residue Handling: The treated solid residue, now free of organic contaminants, is discharged from the desorption unit for further processing or disposal. Depending on the specific contaminants and regulatory requirements, the residue may undergo additional treatment or be disposed of in accordance with applicable regulations.

Applications of Thermal Desorption Units: Thermal desorption units find wide-ranging applications in environmental remediation efforts, including:

-

Soil Remediation: TDUs are used to treat soil contaminated with petroleum hydrocarbons, chlorinated solvents, polycyclic aromatic hydrocarbons (PAHs), and other organic contaminants from industrial spills, leaking underground storage tanks, and historical contamination.

-

-

Sediment Remediation: TDUs are employed to remediate contaminated sediments in rivers, lakes, and harbors, where historical industrial activities have resulted in the accumulation of toxic pollutants.

-

-

Sludge Treatment: TDUs are utilized for the treatment of contaminated sludges generated from wastewater treatment plants, industrial processes, and chemical spills, facilitating the removal of organic contaminants prior to disposal or reuse.

-

-

Brownfield Redevelopment: TDUs play a critical role in the redevelopment of brownfield sites contaminated with hazardous substances, allowing for the restoration of contaminated land for beneficial reuse.

Benefits of Thermal Desorption Units: Thermal desorption units offer several advantages for environmental remediation projects:

-

Effective Contaminant Removal: TDUs provide efficient removal of volatile and semi-volatile organic contaminants from soil, sediment, and sludge matrices, resulting in clean, remediated materials suitable for reuse or disposal.

-

Versatility: TDUs can treat a wide range of organic contaminants, including petroleum hydrocarbons, chlorinated solvents, pesticides, and PCBs, making them versatile tools for addressing diverse environmental contamination scenarios.

-

Volume Reduction: Thermal desorption leads to the volatilization of contaminants, resulting in volume reduction of the treated materials, which can reduce disposal costs and transportation logistics.

-

Compliance Assurance: TDUs enable compliance with regulatory requirements for the remediation of contaminated sites, ensuring that environmental standards and cleanup goals are met or exceeded.

-

Cost-Effectiveness: While initial capital investment may be required, TDUs offer long-term cost savings by providing a sustainable and efficient solution for environmental remediation, minimizing project timelines and liabilities associated with contaminated sites.

留言列表

留言列表

{{ article.title }}

{{ article.title }}